Anycubic Photon Mono M5s SLA 3D Yazıcı

12K Exquisite Details

The Photon Mono M5s is the 12K resolution of its 10.1-inch screen, achieving a 19-micron X accuracy, with printing details as precise as a hair thickness.

Leveling-Free

A leap for printing success

A mechanical sensor on the cantilever arm detects the fit between the printing platform and the floating leveling module and automatically adjusts it based on the detection results. This eliminates the risk of leveling failure, improves printing success rate.

3X[1] Faster

Photon Mono M5s is able to reach a 105mm/h* average printing speed. It uses a high-speed release film able to lower the release force, which ensures a high printing success rate while reducing the release height and increasing the lifting speed.

[1] Printed with Anycubic Photon Workshop 3.1 (or higher) and Anycubic High Speed Resin.

Setting at 0.1 mm layer thickness and 2 mm shell perforation and extraction.

Data from Anycubic Lab, for reference only.

Smart, Simple and Efficient

Auto Device Check

Through multiple tests on the connectivity of the exposure screen, mechanical detection module, and motor operation status, it quickly detects and troubleshoots hardware problems, ensuring smooth and non-destructive connections to help achieve printing success.

Resin Detection

In order to reduce printing failures caused by insufficient resin, the resin detection mode is preset to intelligently detect whether the amount of resin in the vat meets the printing requirements before printing. Minimizes print failures due to resin shortages.

Prints Status Detection

The prints status detection function will provide reminders for common failures like bottoming-out printing, significantly reducing waste of resin and time. It also can smartly analyze the causes of failures, and provides effective suggestions to ensure printing efficiency.

Anycubic App

Popular sliced models/STLs available for you to experience 3D printing in just one touch. Task viewing ensures your printing process in control.

Upgraded Anycubic Photon Workshop 3.1

Intelligent Mode

In the new version of slicing software Anycubic Photon Workshop 3.1, the"Intelligent Mode" option can intelligently match exposure parameters according to model details and size, reduce the risk of printing failure caused by improper parameter settings.

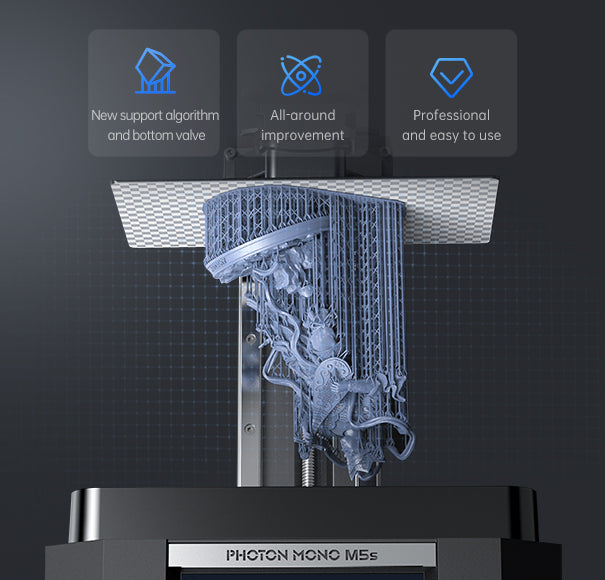

New Support Algorithm

The new support algorithm further improves the printing stability and success rate, reduces damage to the model surface, makes it easy to remove supports and bottom valves. Comprehensively improve the speed of punching and slicing, making slicing easier to use.

Anycubic Photon Mono M5s

Models Display

Anycubic Photon Mono M5s

Video Introduction

Anycubic Photon Mono M5s

In The Box

Kampanyalı Ürünler

3D YazıcılarEn çok tercih edilen ürünlerde sizler için avantajlı fiyatlar

-

200 TL Üzeri Ücretsiz Kargo

Seçilmiş birçok üründe

-

3D Güvenli Ödeme

100% Güvenilir

-

24/7 Destek

Online & Telefon & Mail

.JPG)